Brown corundum is made of natural bauxite as raw material, carbon (mainly coke) is used as reducing agent, and iron filings are added as sedimentation agent (clarifier) to form ferrosilicon deposited on the bottom of electric furnace.

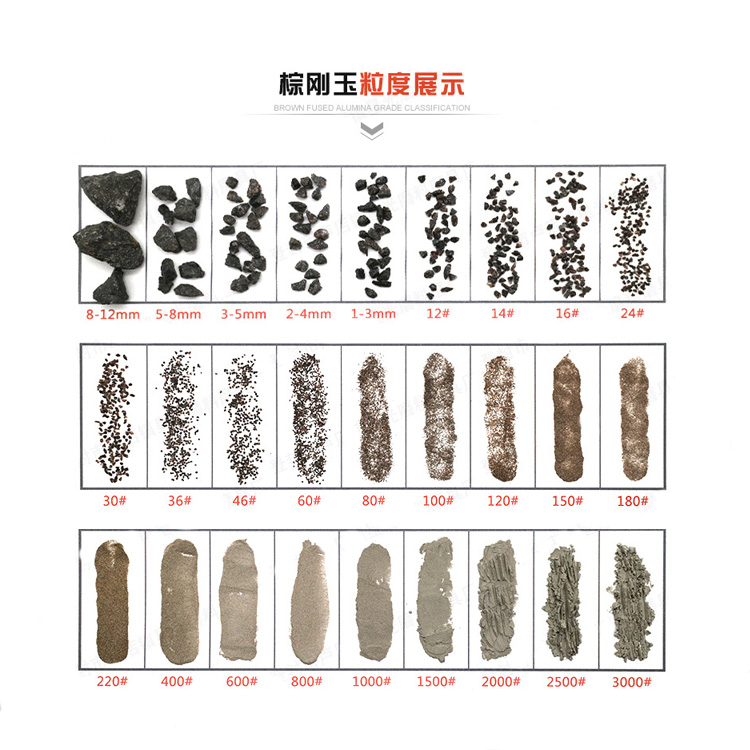

Brown fused alumina for conventional abrasive

Brown corundum is made of natural bauxite as raw material, carbon (mainly coke) is used as reducing agent, and iron filings are added as sedimentation agent (clarifier) to form ferrosilicon deposited on the bottom of electric furnace.

Brown fused alumina is tan, generally A12O3≥94.5%, SiO2≤3.5%, TiO2≤3.5%, FeO3≤1%. The mineral composition is mainly a-Al2O, the central part of the crystal shape is rhombus, thick plate and cracked particles, and there are many silicon oxide and calcium oxide melt crystals around, which are long plate-like, and the coarsest grains are Skeletal platelets. Due to miscellaneous

The quality has not been completely removed, so brown fused alumina also contains secondary crystalline phases such as rutile, as well as glass phases, iron alloys and solid solutions. The hue of brown corundum depends to a large extent on the titanium oxide remaining in the product.

Brown fused alumina is mainly used as abrasive. In recent years, it has been used as an aggregate for large and medium-sized blast furnace tap ditch castables and anhydrous tap mud, and as a raw material for the manufacture of ordinary corundum bricks (including high-alumina silicon carbide bricks).

|

particle size range |

Al2O3% |

TiO2 |

CaO |

SiO2 |

Fe2O3 |

|

0-1,1-3,3-5mm |

95~97 |

1.7~3.40 |

≤0.42 |

≤1.00 |

≤0.30 |

|

F4~F80 P12~P80 |

95.00~97.00 |

1.70~3.40 |

≤0.42 |

≤1.00 |

≤0.30 |

|

F90~F150 P100~P150 |

94.50~97.00 |

||||

|

F180~F220 P180~P220

|

94.50~97.00 |

1.70~3.60 |

≤0.45 |

≤1.00 |

≤0.30 |

|

F230~F800 (P240~P800)

|

≥93.5 |

1.70~3.80 |

≤0.45 |

≤1.20 |

≤0.30 |

|

F1000~F1200 (P1000~P1200) |

≥93.00 |

≤4.00 |

≤0.50 |

≤1.40 |

≤0.30 |

|

P1500~P2500 |

≥92.5 |

≤4.20 |

≤0.55 |

≤1.60 |

≤0.30 |

|

F4~F80 P12~P80 |

≥94.00 |

1.50~4.00 |

≤0.50 |

≤1.40 |

- |

|

F90~F150 P100~P150 |

≥93.00 |

1.50~4.00 |

≤0.50 |

≤1.40 |

- |

|

F230~F800 (P240~P800)

|

≥92.50 |

≤4.20 |

≤0.60 |

≤1.60 |

- |

|

F1000~F1200 (P1000~P1200) |

≥92.00 |

≤4.20 |

≤0.60 |

≤1.80 |

- |

|

P1500~P2500 |

≥92.00 |

≤4.50 |

≤0.60 |

≤2.00 |

- |

White corundum is made from industrial alumina powder, which is smelted in an arc at a high temperature above 2000 ℃ and then cooled. After crushing and shaping, magnetic separation to remove iron, it is divided into various particle sizes.

Brown Fused Alumia powders are fused wIth premium raw materials and 3500 KVA furnace. It is perfect material specifically manufactured to be used for general abrasive applications in bonded abrasive tools, polishing and sandblasting grit. It has lower hardness and abrasive capacity than diamond, boron carbide, and silicon carbide, it is widely used for grinding ferrous materials, finishing tough and hard materials. It is also be used as high-class refractory materials. Brown Fused Alumia is offered in macro and micro powder form, in both F and P grades.

Fireclay bricks are classified as weak acid refractories. Due to the large fluctuation range of chemical composition, different production methods, and differences in firing temperature, the properties of clay bricks change greatly.We can produce all kinds of Fireclay bricks according to customers' requirements

GONGYI YUYING REFRACTORY CO.,LTD is located in GONGYI ZHENGZHOU CITY HENAN province,which is one of the main refractory production bases in China. Main products include different kinds of refractory brick and refractory material :Such as Fire Clay Brick, High Alumina Brick, Light Weight Insulating Brick,expanded clay,ceramic fiber blanket,rock wool products etc.They are widely used in Iron and steel, Nonferrous metals, BuildingMaterials(Cement,Glass,Ceramic), Petrochemical, Energy & Incineration etc industries.

Silica brick: an acidic refractory mainly composed of tridymite, cristobalite and a small amount of residual quartz and glass phases. Its silica content is more than 94%, it has anti-acid slag erosion performance, high high temperature strength, high load softening temperature, long-term use in high temperature flower wells without deformation, but low thermal shock stability (heat exchange in water is 1-4 Second-rate).

Special Acid-proof Brick Lightweight acid-proof Brick Acid resistant brick is the ideal choose for your project with their features of proof pressure, corrosion resistance, easy to clean and acid-base resistance.

YY Refractory supplies premium-grade ramming material (ramming mass) for blast furnaces. Heat-resistant, erosion-proof, and easy to apply. Boost furnace longevity & efficiency. ISO-certified. Get a quote today!

Refractory wet mud used to block the iron outlet can be divided into two categories: water cannon mud and waterless gun mud. On large and medium -sized blast furnaces on high top pressure and high degree of smelting.