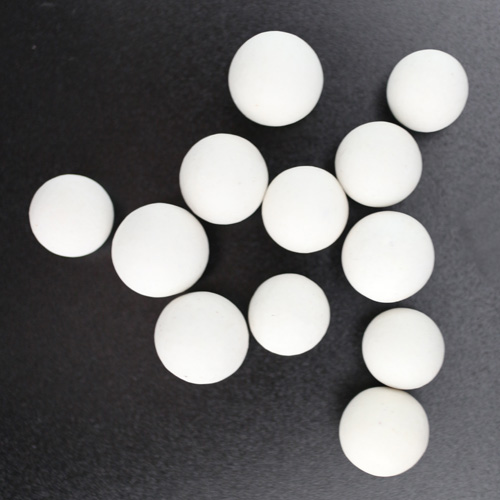

Polishing high alumina ceramic ball for ball mill

The microcrystalline wear-resistant alumina ball is a high-quality grinding medium made of selected high grade material, advanced molding technology and calcined in high temperature tunnel kiln. Possessed with high density, high hardness, low wear, good seismic stability and good corrosion resistance, the products are the most ideal medium for grinding glaze, blank and mineral powder processing, and are used as the grinding medium of ball mill in ceramics, cement, paint, refractory, inorganic mineral powder and other industries.

We can produce products according to customers' specification.

|

Items |

Content |

Others |

Hardness |

Bulk Density |

Self Wear Rate |

Water Absorption |

|

92% Alumina Balls |

≥ 92% |

<8% |

≥9 |

>3.63 |

<0.01% |

<0.01% |

|

80% Alumina Balls |

≥ 80% |

<20% |

≥8 |

>3.30 |

<0.02% |

<0.02% |

|

68% Alumina Balls |

≥ 68% |

<32% |

≥7 |

>3.00 |

<0.03% |

<0.02% |

Normal size:1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm. 70mm, 80mm, 90mm, 100mm These sizes our factory produce regular, many of them are in large stock.

Normal size: 20mm, 25mm, 30mm, 40mm, 50mm, 60mm. 70mm These sizes our factory produce regularly, many of them are in large stock.other sizes beyond this range, also could produce for you, please contact us to get more infos.

Normal size: 30mm,40mm,50mm,60mm. These four sizes have very large stock.

Application:

In a certain operating and regeneration conditions,Active alumina ball desiccant has drying depth of up to -40 degrees below the dew point, is a trace of water depth of the desiccant efficient, single molecule adsorption layer of net heat, So very suitable for non-thermal regeneration device.

① Active alumina ball desiccant can be used as a defluorination agent of high fluoride drinking water (fluoride removal capacity), alkyl benzene production cycle of defluorination agent, transformer oil deacidification regeneration agent;

② Activated alumina ball desiccant can be used as oxygen desiccant for the oxygen industry, textile industry, automatic instrument, chemical fertilizer and petrochemical industry, and the dew point of PSA in the air separation industry can reach -55 degrees;

③ High-performance activated alumina ball in the unshaped refractory ingredients can bring the following benefits: to improve the density of the body, fluidity, strength, increase the amount of secondary mullite, reduce the water and porosity;

④ In addition as a desiccant, the active alumina ball can also be contaminated with oxygen, hydrogen, carbon dioxide, natural gas and other lubricants in the adsorption of steam;

⑤ Active alumina ball can be used as a catalyst, catalyst carrier, chromatography analysis of the carrier.

Packing

① Packing: 25kg / bag (lined with plastic bags, the outer layer of plastic laminated bags). This product is non-toxic, to be waterproof, moisture-proof, non-oil and oil contact with steam.

② Transport: Do not drag with iron hook, prevent to be mixed with hard materials, not strong vibration, friction, step on, smashing, throwing is prohibited, should be light loading and unloading to reduce the packaging broken.

③ Storage: Store in a cool and dry place, to prevent the rupture of inner and outer bags, to prevent moisture and other substances affect the use of results, storage away from sources of pollution; Do not open the package before use, so as not to absorb moisture and affect the use of results.

④ Applicable conditions: activated alumina ball desiccant is for deep drying, pressure> 5kg/cm2 is appropriate.

⑤ Regeneration: activated alumina ball on gas, water vapor and some liquid moisture has selective adsorption capacity. Adsorption saturation can be heated at about 175-315°C to remove water and resurrection, adsorption and resurrection can be carried out several times.

The unshaped refractory material used when repairing the lining of thermal equipment by spray construction method is called refractory gunning material. It is made of a refractory set with a certain particle gradation

Brown corundum refractory brick is made of fused corundum as the main raw material. It is formed by high pressure and fired at high temperature. It has high thermal shock stability, low porosity, low expansion, good resistance to melt vapor and gas erosion, and excellent oxidation resistance. Dimensionally accurate advantages.

Corundum bricks are mainly used in iron-making blast furnaces and blast furnace hot blast furnaces, refining furnaces outside steel-making furnaces, sliding water heaters, glass melting furnaces and petrochemical industrial furnaces, etc.

Insulation castables are mainly made up of lightweight refractory aggregates, powders, and binder additives.

The alumina ball is also called the high aluminum accumulation of heat ball.High alumina refractory ball is based on bauxite as the mainly raw refractory material.Adding powder and additives and anchoring agent.After proportioning, molding and high sintering to make it.The production engineering of high alumina refractory ball is similar to that of high alumina refractory brick.It should be based on the properties of raw materials,high alumina refractory ball requires production conditions and other factors to determine.

The heavy part of the raw materials for the chrome zirconium corundum composite brick is sintered tabular corundum, high-purity chromium oxide, high-purity zircon, and Guangxi white cement.As the main raw material, the light part of the raw material is made of 47 mullite, kyanite, floating beads and coke gemstones as the main raw materials. During molding, a separator is set in the middle of the mold, and heavy materials and light materials are added at both ends. After high pressure molding , finished products made of high temperature sintering.

Special Acid-proof Brick Lightweight acid-proof Brick Acid resistant brick is the ideal choose for your project with their features of proof pressure, corrosion resistance, easy to clean and acid-base resistance.

Anti stripping high alumina bricks are referred to as anti-stripping bricks or anti-stripping refractory bricks. Anti-stripping high-alumina bricks are widely used in my country's new dry process kiln, Libore kiln and wet process kiln, including kiln door cover, rising flue, cooling zone, decomposition zone, safety belt, transition zone, coolant rear Walls and side walls and beams with curved ceilings.