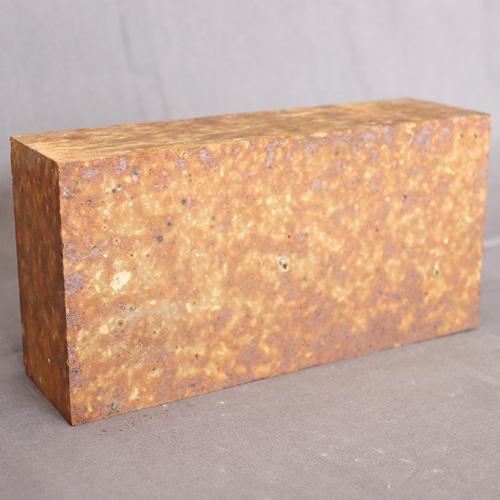

silicon mullite brick is a kind of refractory brick product made of super high alumina bauxite and silicon carbide as raw materials through a special sintering process. It has the characteristics of continuously forming a protective layer and reducing ring formation, and its heat resistance is also very good. The softening temperature under load can reach 1600 ℃, and the service life is long. Mainly used in the transition zone, decomposition zone and cooler of small and medium-sized cement kilns.

silicon mullite bricks for cement kiln

silicon mullite brick is a kind of refractory brick product made of super high alumina bauxite and silicon carbide as raw materials through a special sintering process. It has the characteristics of continuously forming a protective layer and reducing ring formation, and its heat resistance is also very good. The softening temperature under load can reach 1600 ℃, and the service life is long. Mainly used in the transition zone, decomposition zone and cooler of small and medium-sized cement kilns.

silicon mullite bricks are phosphate-bonded high-alumina bricks and phosphate-bonded high-alumina wear-resistant bricks, which are made of dense bauxite clinker as aggregate, phosphoric acid and phosphate as binders, and are produced by high pressure molding and medium temperature heat treatment. become. The thermal stability, wear resistance and chemical resistance of the product are excellent, but the high temperature performance is poor. It is widely used in the preheating zone of the rotary kiln, the decomposition zone and the kiln door cover, the inner lining of the cooler, etc. The ordinary high-alumina bricks were dipped in phosphate, and after being dried and taken out, it was found that the load softening temperature of the original high-alumina bricks increased. After phosphate impregnation, the porosity is significantly reduced, the bulk density is increased, and the flexural strength is significantly improved. Impregnating high-alumina bricks with phosphate can improve the quality of high-alumina bricks and prolong their service life.

|

index |

|

||

|

GMI1 650 |

GMI1 600 |

GMI1 550 |

|

|

Al2O3 % ≥ |

65 |

63 |

60 |

|

Bulk density (g/cm3)≥ |

2.65 |

2.60 |

2.55 |

|

Apparent porosity% ≤ |

17 |

17 |

19 |

|

Compressive strength/Mpa≥ |

85 |

90 |

90 |

|

softening temperature under load ≥ |

1650 |

1600 |

1550 |

|

Thermal shock stability (1100℃)/time≥ |

10 |

10 |

10 |

|

Abrasion resistance at room temperature/cm3≥ |

5 |

||

silicon mullite bricks features:

Good thermal shock stability

Does not break during use

Does not flake off

Corrosion resistant

The service life is significantly extended.

The compressive strength and load softening temperature of silica molybdenum bricks are significantly higher than those of anti-stripping high-alumina bricks, and their thermal shock stability, corrosion resistance and wear resistance are good, but their thermal conductivity is not high. It is exactly what is required by the process characteristics of the rear transition zone, and the service life is 1.5 to 2 times that of the anti-stripping brick. It has good wear resistance and is more suitable for cooling belts, and its service life can reach more than two years, which is 3 to 5 times that of high alumina bricks.

At present, according to the use conditions of different sections of the rotary kiln, silica mulberry bricks with different performances have been applied. In some large kilns with a daily output of 5,000 tons, refractory manufacturers have upgraded their products - silicon red bricks based on their experience to meet the needs of different kiln types.

Now, it can be said that silica molybdenum brick is the best choice for refractory material for the transition zone of cement rotary kiln.

The alkali-resistant brick for cement kiln has the characteristics of strong alkali erosion resistance, good thermal shock resistance and high cost performance.

The heavy part of the raw materials for the chrome zirconium corundum composite brick is sintered tabular corundum, high-purity chromium oxide, high-purity zircon, and Guangxi white cement.As the main raw material, the light part of the raw material is made of 47 mullite, kyanite, floating beads and coke gemstones as the main raw materials. During molding, a separator is set in the middle of the mold, and heavy materials and light materials are added at both ends. After high pressure molding , finished products made of high temperature sintering.

We specialize in producing various types of tap hole clay. Our tap hole clay protects the blast furnace hearth, increases production and saves costs! We are your best choice for tap hole clay suppliers.

The refractoriness of clay bricks is comparable to that of silica bricks, up to 1690~1730℃, but the softening temperature under load is more than 200℃ lower than that of silica bricks. Because in addition to the high refractory mullite crystal, the clay brick also contains nearly half of the low melting point amorphous glass phase.

The alumina ball is also called the high aluminum accumulation of heat ball.High alumina refractory ball is based on bauxite as the mainly raw refractory material.Adding powder and additives and anchoring agent.After proportioning, molding and high sintering to make it.The production engineering of high alumina refractory ball is similar to that of high alumina refractory brick.It should be based on the properties of raw materials,high alumina refractory ball requires production conditions and other factors to determine.

Silica brick is an acidic refractory mainly composed of tridymite, cristobalite and a small amount of residual quartz and glass phases

Yuying Refractory produces a complete set of refractories for electrolyzers, and the new impermeable bricks are used in conjunction with impermeable castables

Fireclay bricksis suitable for supporting hot blast stoves of large, medium and small blast furnaces