Converter, electric furnace gunning material has the characteristics of high adhesion rate, good high temperature corrosion resistance, etc.

Converter and electric furnace gunning material

Converter and electric furnace gunning materials have the characteristics of high adhesion rate and good corrosion resistance at high temperature, especially in rotating furnaces.

Furnace, electric furnace later use effect is better. This product can be carried out in the furnace temperature between 300~1700C

For gunning, the amount of water added is generally about 15%, and it can also be adjusted according to the furnace temperature to achieve satisfaction

use effect. In the process of transportation and storage, attention should be paid to moisture-proof, so as not to agglomerate and affect the use effect.

The fruit has a shelf life of two months.

|

Chemical composition |

Physical properties |

|||

|

MgO% |

≥81 |

Bulk density g/cm3 |

2.70 |

|

|

CaO% |

≤7.87 |

Refractorines ℃ |

1800 |

|

|

Fe2O3% |

<3.15 |

The attachment rate% |

85 |

|

|

SiO% |

≤4.2 |

Bending strength MPa |

1300℃×3h |

>4 |

|

Al2O3% |

≤2.1 |

1600℃×3h |

>8 |

|

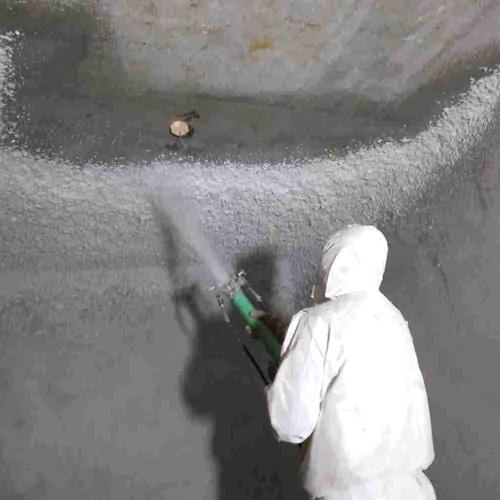

Converter and electric furnace gunning material construction requirements

1. Dry gunning is used, and water is added to the gun head.

2. Air pressure 5-8kg/cm, water pressure 4-5kg/cm.

3. When spraying, the distance between the gun head and the surface of the construction body should be kept 0.8-1m.

4. The thickness of one shot should not be greater than 30-50mm.

5. This material is suitable for hot repair of various converter furnace trees

The unshaped refractory material used when repairing the lining of thermal equipment by spray construction method is called refractory gunning material. It is made of a refractory set with a certain particle gradation

Acid resistant refractory gunning material is used for spraying of blast furnaces, hot blast stoves, hot blast pipes, flue protection layers, working layers, etc.

Corundum bricks are mainly used in iron-making blast furnaces and blast furnace hot blast furnaces, refining furnaces outside steel-making furnaces, sliding water heaters, glass melting furnaces and petrochemical industrial furnaces, etc.

Corundum self flowing castable is a high-tech product developed according to the theory of solid fluid and combined with the application characteristics of refractory materials, which is the first in China. The corundum self-flowing material can be degassed and leveled without vibration with the help of its own gravity, so as to achieve densification.

Brown corundum is made of natural bauxite as raw material, carbon (mainly coke) is used as reducing agent, and iron filings are added as sedimentation agent (clarifier) to form ferrosilicon deposited on the bottom of electric furnace.

Refractory wet mud used to block the iron outlet can be divided into two categories: water cannon mud and waterless gun mud. On large and medium -sized blast furnaces on high top pressure and high degree of smelting.

Common low-creep high-alumina bricks can be used in blast furnace hot blast stoves, as well as other industrial kilns, and can also be made into low-creep high-alumina bricks of different sizes according to specific construction requirements, such as lattice bricks, special-shaped bricks, anchor bricks, etc. , mainly used in industrial kilns in long-term high temperature environments

The alumina ball is also called the high aluminum accumulation of heat ball.High alumina refractory ball is based on bauxite as the mainly raw refractory material.Adding powder and additives and anchoring agent.After proportioning, molding and high sintering to make it.The production engineering of high alumina refractory ball is similar to that of high alumina refractory brick.It should be based on the properties of raw materials,high alumina refractory ball requires production conditions and other factors to determine.